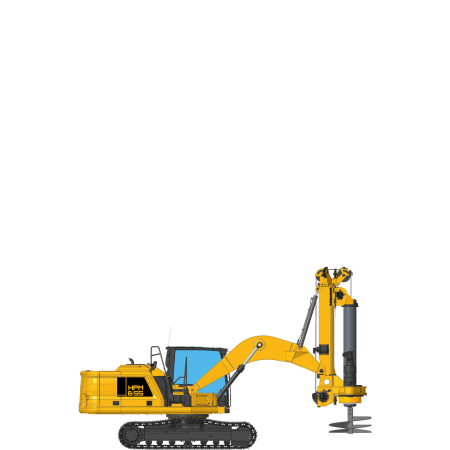

B55

| Base | CAT®317 |

|---|---|

| Drilling Depth | 19 m61' ft |

| Drilling Diameter | 2750 mm9' ft inc |

| Operating Weight | 25500 kg56200 lbf |

| Rotary Effective Torque | 56000 lb.ft76 kNm |

Over obstacles, and beyond!

The newly designed articulation system allows the mast to reach difficult drilling points. Compared to the HPMs with standard kinematics system, these models have a great range of working radios making it ideal for applications such as utilities drilling, transmission lines and substation, drilling on a steep slopes and difficult ground.

B55

Over obstacles, and beyond!No matter where, into tight spaces and/or at difficult reach, the B55 can handle it. With its ability to drill to a depth of 19 meters and with a great tool capability, the B55 will amaze you in terms of flexibility.

Mounted on CAT®317 base, equipped with a CAT C4.4 Stage V engine, which meets U.S. EPA Tier 4 Final, EU Stage V and Japan 2014, The B55 can count on all the technology and reliability of a CAT base and arm along with HPM technology and innovation.

Do you also need it versatility? B55 It can easily be converted from the standard version to the short version.

And finally forget transports permits, the B55 rig down to a compact size resulting easy to move from one construction site to another.

Low-headroom Configuration

This HPM can be quickly and safely converted in Short Mast configuration allowing it to work in limited heights job sites, such as under bridges or below power lines.

Comfort Cabin

The HPM cabin is equipped with a comfy and wide adjustable seat. The standard automatic air conditioning keeps the cabin at the ideal temperature throughout the day.

All machine interfaces are ergonomically positioned and designed for optimum control and efficiency. The easy accessible keyboards allow the operator to quickly get the rig ready to drill.

Automatic Functions

Automatic functions allow the operator to reduce rig-up time and get the most in productivity.

With a push of a button, the operator can make use of automatic functions, including: Verticality of the mast, Automatic Rig-up, Automatic return to drilling point and rotary auto drive.

Drilling Cruise Control

The HPM software includes the enabling of the drilling cruise control. When the system is enabled, the operator can preselect the rotary gear so it’s speed. With a push of a button the system can be activated and the operator can also lock the crowd pressure for a complete automatic drilling mode. Safety systems can disable the function immediately.

Remote Control

Increase safety and flexibility when loading or unloading the equipment. The operator can make use of different viewing angles while moving the machine from outside the cabin. Having a complete view of the rig during these phases allows the operator to make sure that hoses, wirings and wire ropes are safely positioned. Drilling functions are enabled through the remote control for a safe service and maintenance of the rig.

Technical data

All data presented refers to the standard model and may vary based on specific equipment configuration and customer requirements.

Need more torque, pull or depth? Contact us to explore the full range of configuration options.

| Base | CAT®317 |

|---|---|

| Engine Type | C4.4 |

| Installed Power | 130 hp97 kW |

| Max. Effective Torque | 56000 ft.lbs76 kNm |

|---|---|

| Working Speed | 7-30 rpm |

| Discharge Speed | 60-100 rpm |

| Main winch pull | 22000 lbf98 kN |

|---|

| Crowd Type | Winch Crowd System |

|---|---|

| Max. crowd force | 103 kN23150 lbf |

| Crowd Stroke | 13'6" ft inc4100 mm |

| Drilling Depth | 19 m61' ft |

|---|---|

| Drilling Diameter | 2750 mm9' ft inc |

| Operating Weight | 25500 kg56200 lbf |

|---|---|

| Transport weight | 25500 kg56200 lb |

| Transport width | 102 ft inc2590 mm |

| Transport height | 118" ft inc3000 mm |